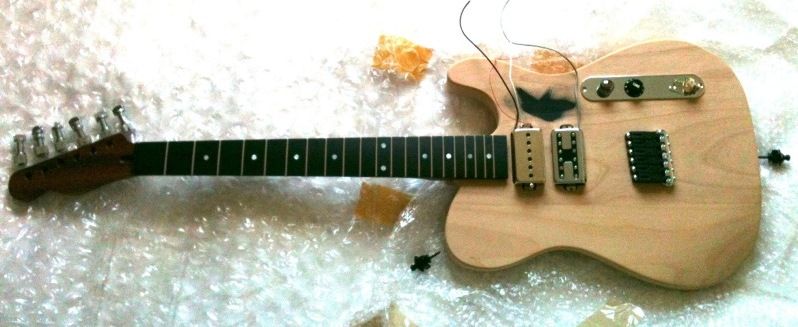

I'm currently building a guitar from parts and I finally have all the pieces together:

I've not done this before so it's all very exciting (for me if not for anyone else!). I'm having a local luthier do some of the more tricky jobs (installing the bridge and the nut, dressing the frets) but I'm going to stain, finish and bolt everything together myself. The guitar is going to be black from tail to toe, apart from a bit of chrome here and there. Very rock 'n' roll.

Being the adventurous and slightly obsessive soul that I am, however, instead of using paint, polyurethane or woodstain I've decided to colour the wood using a kind of chemical ebonising treatment that involves rusty iron dissolved in vinegar.

This is a fairly well known technique and lots of information can be found online about it. The iron/rust + the acetic acid in the vinegar (roughly 5%) = iron acetate and this reacts with the tannins in the wood, changing the colour of the wood fibres themselves. On darker woods such as mahogany the wood can go completely black. However, lighter woods turn a greyish-blue colour, which can look very nice but isn't what I'm after.

One method for strengthening the chemical reaction is to treat the wood with tea, which increases the tannin content of the wood and, consequently, makes the wood much darker when the iron acetate is added. However, I wanted to see how far I could take the process so I bought 100g of pure (minimum 96.5%), powdered tannic acid for £7.79 plus shipping from an online chemicals shop.

The tea method works well but the pure method is astonishing.

But let's back up: there are several how-to guides online but here's what I did:

To make the iron acetate:

1. Take some 0000 grade, oil-free (wash if necessary) steel wool, fray it (i.e. pull it apart a bit), get it damp and leave it out for a few days, until it turns rusty.

2. Put the resulting rusty mess into a jar and add just enough vinegar (I used normal, clear pickling vinegar) to submerge the wool.

3. Cover it up but be sure to leave some way for gas (mostly oxygen) to escape as the jar might burst otherwise.

4. Leave the concoction for a few days until the wool has mostly dissolved.

5. Strain your solution through a coffee filter into a fresh container to remove all remaining bits and lumps.

6. Let the solution settle and you should have a clear-ish layer on top and a load of reddish-orange gunk underneath.

The clear-ish stuff is your iron acetate. Apply this to the bare wood and you'll see the reaction in a few minutes. To strengthen the reaction using tea just brew a small amount as strong as you can and apply it to the wood, letting it soak in a bit before adding the iron acetate. This works well enough. With the powdered tannic acid I took just half a teaspoon (a tiny, tiny amount) dissolved that with just enough water to dissolve the powder and applied it to the wood in the same manner as the tea.

Here I've added a stripe of tea (on the right) and tannic acid (on the left). I let it all dry before adding the iron acetate:

Immediately (approx. 10 seconds) after adding the iron acetate (left=tannic acid+iron acetate, middle=tea+iron acetate, right=iron acetate on its own):

And after letting everything dry (took about 10 minutes):

Up close with tannic acid:

Up close with tea:

Up close with just iron acetate:

As you can see the reaction with the tannic acid is spectacular. The colour changes instantly (it's like adding milk to coffee -- it's that quick) and it dries with a really nice, solid black result. The tea-treated and un-treated stripes look about the same in these pictures. In reality the tea-treated one is a slightly darker. Regardless, between the tea and the tannic acid there's no comparison.

I'm still experimenting with the technique (as you can see!):

One treatment is enough to turn the wood black but I think several treatments with a light sanding inbetween works better as it smooths out any raised grain, removes any excess residue and gets the colouring a little bit more even and consistent.

This is a very, very cheap and really satisfying way of colouring any kind of wood. I reckon I could colour hundreds of guitars with that 100g bag of tannic acid and if it works on something as pale as alder it should work on anything. The best thing with this technique (and this is exactly what I was hoping for) is that because you're actually changing the colour of the wood fibres themselves in accordance with their own chemistry you keep the detail of the grain visible up close instead of just piling layers of pigment on top of it. You get a nice, dark finish but the natural variation in the wood's texture, grain structure and chemical composition still leaves a little variation in the end product.

What a way to spend your weekend.